Oil & Gas

AODD Pumps

In the oil and gas industry, Diaphragm pumps are valued for their versatility, reliability, and robustness. They excel in handling a wide range of fluids, from thick crude oil to abrasive slurries and corrosive chemicals, all while maintaining safety and efficiency. Their ability to operate in harsh environments, pump a variety of fluids, and maintain a leak-free operation makes them indispensable in Transfer of crude oil, waste management, lube oil systems, glycol dehydration, and emergency drainage applications. For industries with high demands for durability and performance, diaphragm pumps remain a critical piece of equipment in maintaining smooth operations

Air Motors

In hazardous environments like oil and gas, electrical motors pose the risk of sparking, which can ignite flammable gases. Pneumatic motors, being powered by compressed air, eliminate this risk and are intrinsically safe for use in these settings, These motors are designed to withstand extreme temperatures, moisture, and dust, making them ideal for offshore rigs and refineries.

Pneumatic vane motors are used in drills, winches, and valve actuators in the oil and gas industry.

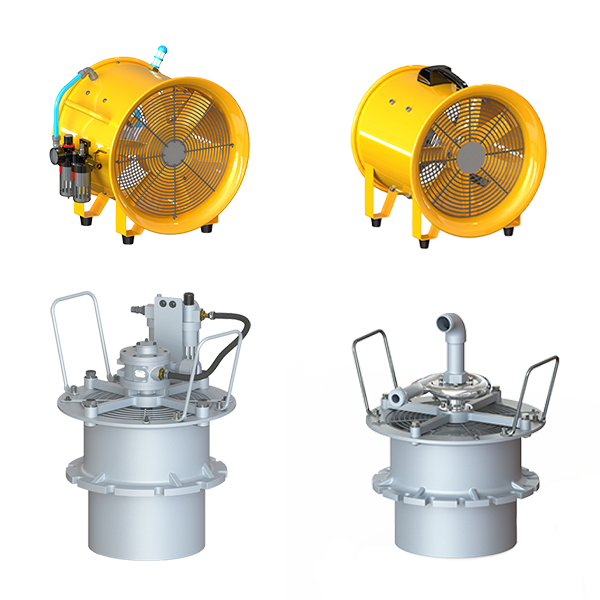

Ventilation Fans

Ventilation fans play a critical role in the oil and gas industry, particularly in maintaining safety and operational efficiency in hazardous environments. Given the presence of flammable gases, vapors, and harsh working conditions, proper ventilation is essential to ensure the safety of personnel, equipment, and facilities. Here’s an overview of how ventilation fans are used in the oil and gas sector. Oil and gas processing environments often involve the handling of flammable or toxic gases such as methane, hydrogen sulfide (H₂S), and volatile organic compounds (VOCs). Ventilation fans are used to remove these dangerous gases from enclosed spaces to prevent the buildup of explosive or toxic concentrations.

Submersible pumps

Pneumatic submersible pumps play a crucial role in the oil and gas industry, particularly in harsh and hazardous environments where traditional electrical pumps may not be suitable. These pumps are designed to operate under challenging conditions, such as high temperatures, deep wells, and areas with explosive gases. These pumps are integral to maintaining safe, efficient, and environmentally responsible operations in the oil and gas industry, especially in hazardous, remote, or extreme conditions. Their versatility, safety, and reliability make them indispensable in a wide range of applications, from dewatering and waste management to emergency response and chemical handling.

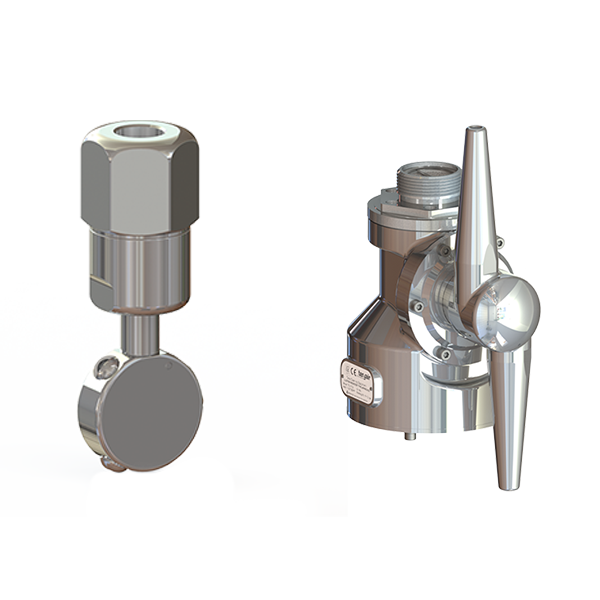

Tank Cleaning Jets

tank cleaning jets are used to clean medium and large tanks, and are often the only viable option for tanks over 6 meters in diameter. These are essential tools in the oil and gas industry, where the cleaning and maintenance of storage tanks, process vessels, and pipelines are critical for operational efficiency, safety, and compliance with regulatory standards. These cleaning jets use high-pressure water, chemicals, or a combination of both to clean the interior surfaces of tanks, removing residues, sludge, scale, and other deposits that accumulate during storage and processing.