Chemical

AODD Pumps

air-operated diaphragm pumps are integral to the chemical industry, offering safe, reliable, and versatile solutions for handling a wide range of fluids and chemicals, while minimizing risks and meeting strict safety and environmental standards. These Pumps are used to transfer corrosive chemicals from storage tanks to reactors, process vessels, or other equipment in chemical processing plants. They are capable of transferring highly corrosive substances such as sulfuric acid, hydrochloric acid, and caustic soda. Their construction materials, such as PTFE (Teflon), PVDF (polyvinylidene fluoride), and other chemically resistant plastics or metals, ensure that the pump’s internal components are not damaged by aggressive chemicals. Many diaphragm pumps used in the chemical industry are made from chemically inert materials, ensuring that the pump does not react with the substances being transferred, which is critical when dealing with reactive chemicals.

These pumps are also used for dosing of chemicals in batch reactors, continuous blending systems, and chemical feed systems for blending and mixing processes.

Air Motors

Pneumatic motors can offer precise control over torque and speed, making them suitable for delicate laboratory equipment or precise chemical handling systems. These motors can be made from materials like stainless steel, which are highly resistant to corrosive chemicals and gases used in laboratories and chemical plants. They are used in mixers, pumps, and agitators to handle chemicals safely and efficiently.

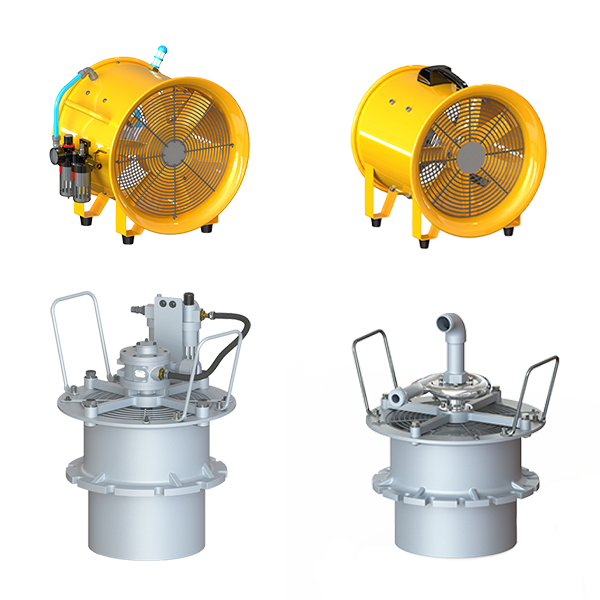

Ventilation Fans

Ventilation fans are an essential part of the chemical industry’s infrastructure, ensuring that air quality, safety, and environmental standards are maintained in the presence of hazardous, corrosive, or flammable substances. They contribute to worker safety, process efficiency, and overall plant reliability by controlling airborne contaminants, managing temperature and humidity, and preventing explosions. Properly designed and installed ventilation systems tailored to the specific needs of chemical processes are crucial for the safe and efficient operation of chemical plants.

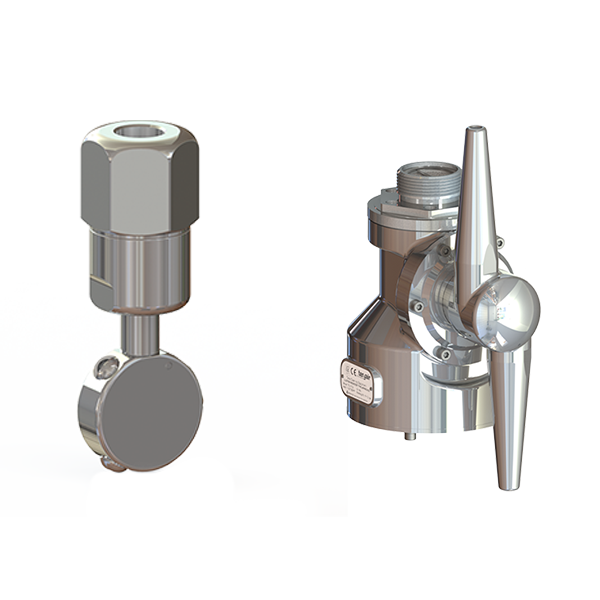

Tank Cleaning Jets

Tank cleaning jets are crucial in the chemical industry for ensuring the cleanliness and safety of storage tanks, reactors, and process vessels. These systems are used to clean the internal surfaces of tanks that store or process chemicals, which can include corrosive substances, hazardous materials, or viscous products that leave behind residues. Their ability to handle hazardous chemicals, prevent cross-contamination, and automate cleaning processes makes them essential in environments where cleanliness and safety are critical. These systems not only enhance safety by reducing manual cleaning efforts but also improve plant efficiency, reduce downtime, and contribute to regulatory compliance.