Cosmetic & Pharma

AODD Pumps

Air-operated diaphragm pumps are essential tools in the cosmetic and pharmaceutical industries due to their versatility, hygienic operation, and ability to handle a wide variety of fluids, including viscous, abrasive, and delicate materials. pumps are used to transfer high-viscosity cosmetic products such as lotions, creams, gels, and pastes. These pumps are perfect for transferring shear-sensitive materials such as emulsions and suspensions used in makeup, shampoos, and conditioners. These products require careful handling to avoid separation or degradation. Many pharmaceutical formulations, including vaccines, suspensions, and blood products, are sensitive to shear. AODD pumps are used to transfer these fluids while maintaining their stability. Their role in maintaining product integrity, ensuring hygiene, and reducing risks associated with electrical sparks or contamination makes them indispensable in the production of high-quality cosmetics and pharmaceuticals.

Air Motors

Air motors are widely used in the cosmetic and pharmaceutical industries due to their ability to operate safely in environments where precision, cleanliness, and explosion-proof capabilities are required. These motors are employed in pharmaceutical mixing operations for creating syrups, suspensions, and other drug formulations where homogeneity is critical. They are often used in reactors or blending tanks. They are also used to power mixers and agitators in the production of creams, lotions, gels, and emulsions. Cosmetic formulations often require precise blending of ingredients to maintain consistency, texture, and quality.

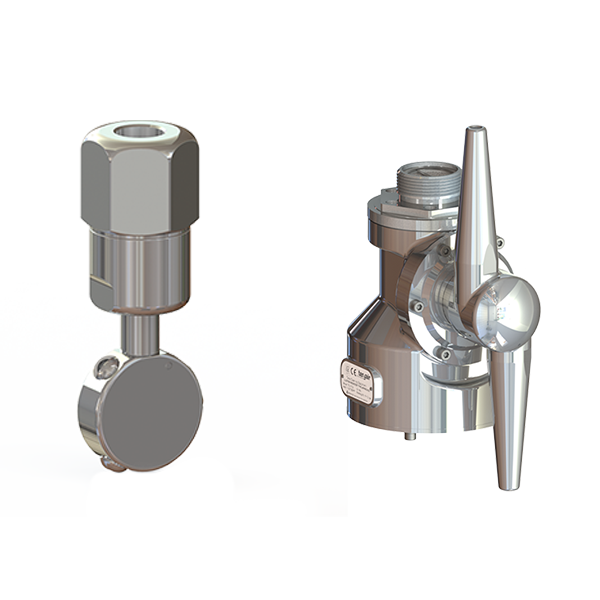

Tank Cleaning Jets

Tank cleaning jets play a crucial role in ensuring the cleanliness and hygiene of storage and process tanks in both the cosmetic and pharmaceutical industries. These industries require tanks to be thoroughly cleaned to prevent contamination and maintain product integrity. Tank cleaning jets, also known as tank cleaning nozzles or spray balls, provide automated, efficient, and consistent cleaning by delivering high-pressure jets of water or cleaning solutions.

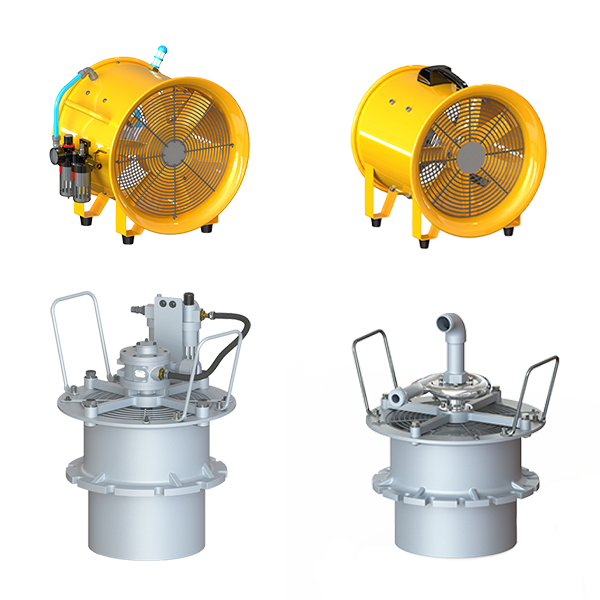

Ventilation Fans

Ventilation fans are essential in the cosmetic and pharmaceutical industries to maintain clean, safe, and regulated environments. These industries require strict air quality standards to prevent contamination, ensure worker safety, and maintain product integrity. Ventilation fans play a key role in controlling temperature, humidity, and airborne particles.